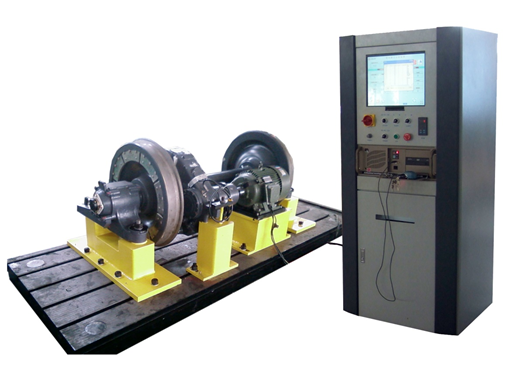

Wheelset bearing running test bench

1. Equipment Use

The wheelset bearing running test bench is an auxiliary equipment in the test section of the main section of the main building and the comprehensive base inspection. The test stand is suitable for the idling routine of the wheel-to-drive unit (wheel, axle, axle box and gearbox) of the subway vehicle. Run-in test, idling run-in test on one wheelset at a time, can run-in on the wheel-to-shaft box bearing and gearbox gear, and can also detect the shock frequency vibration and temperature rise of the axle box bearing and the drive bearing to judge whether the bearing itself and the installation are normal. . At the same time, it is also used for the internal cleaning of gear wheels in various types of vehicles.

2. Main functions

1) The electrical control system of the equipment adopts the advanced and reliable computer system as the core. The equipment can be set by the computer to test the running conditions. The test can be completed by 1-2 operators.

2) The system adopts frequency conversion technology to make the starting and braking smooth and reliable.

3) The equipment can realize forward and reverse running, and the operation modes are divided into manual and automatic. The test bench is equipped with a gearbox hoisting/top mounting fixture to meet the fixing of the gearbox during the running of the moving wheel.

4) The setting of the running-in parameters is flexible and convenient, and the operator can adjust the parameters such as the upper limit of temperature rise, the running-in time, and the maximum running speed according to the process change.

5) The height of the equipment is required to be below the basic ground. There is a protective fence around it. The equipment is required to be connected with a section of the rail and the inspection line so that the wheel pair can be directly moved to the equipment for fixing.

6) It has high-speed oil washing and low-speed oil washing function. It has braking function at the end of oil washing, shortening wheel-to-idle time and adjustable braking force; the equipment reserves the interface with bearing shaft box cleaning.

3. Main structural composition

The equipment is mainly composed of a wheelset gear box fixed platform, a driving device, an electric control system and a lubricating oil filtering system.

4. Main Technical Parameters

|

1 |

Driving mode |

Drive wheel pair gearbox |

|

2 |

Gauge |

1435mm |

|

3 |

Running speed |

0-135km/h adjustable |

|

4 |

Running-in time |

≥ 5min (user can set) |

|

5 |

Stopping time |

≤1 min |

|

6 |

Temperature measurement range |

-10℃-100℃ |

|

7 |

Temperature measurement accuracy |

≤1℃ |

|

8 |

Operating noise level |

≤80db(A) |

|

9 |

Power supply |

AC380V±10% 50HZ three-phase five-wire system |

|

10 |

Input power |

25Kw |

5. Equipment pictures

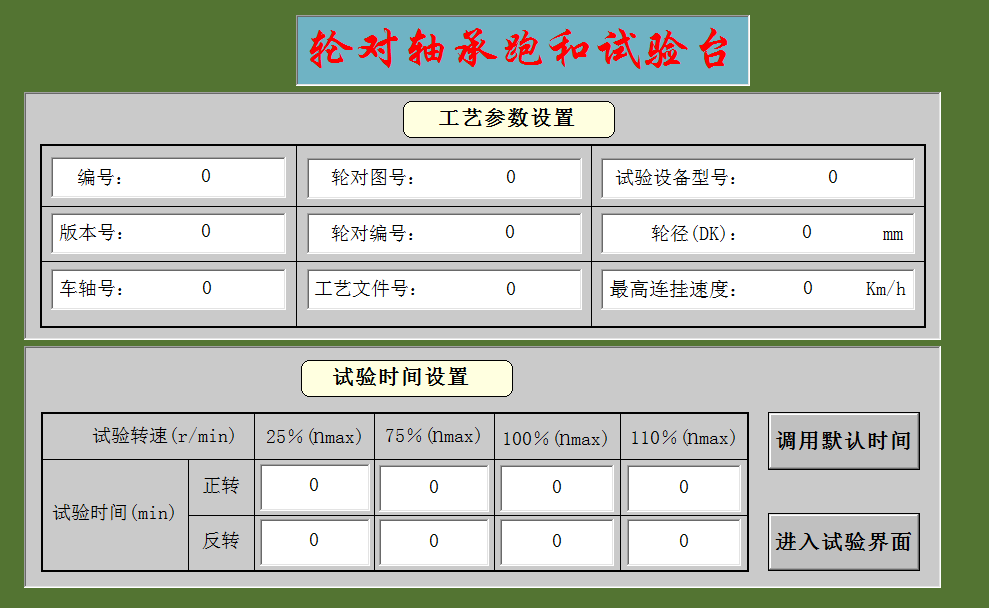

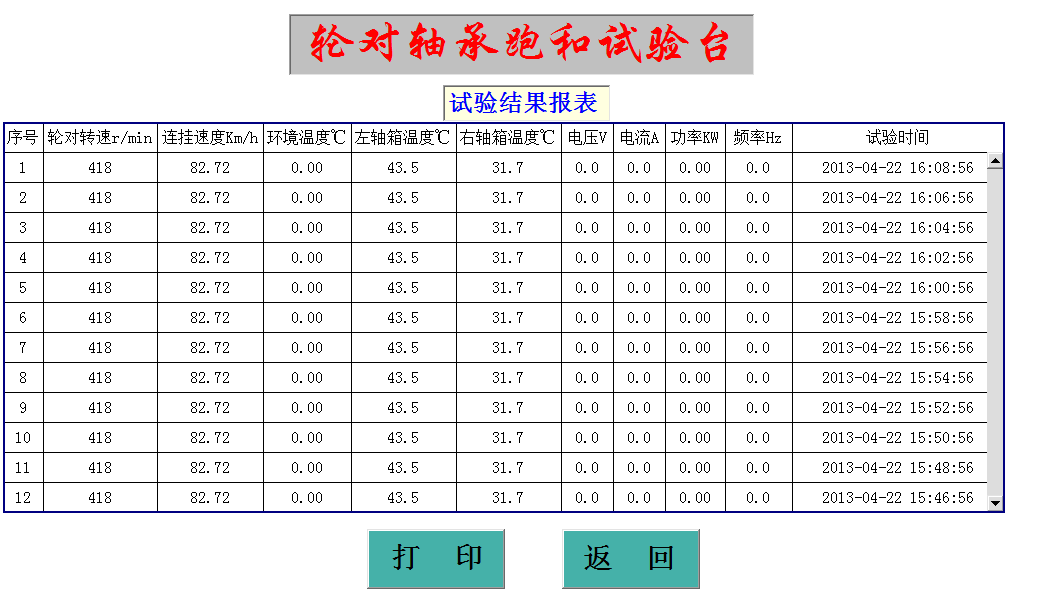

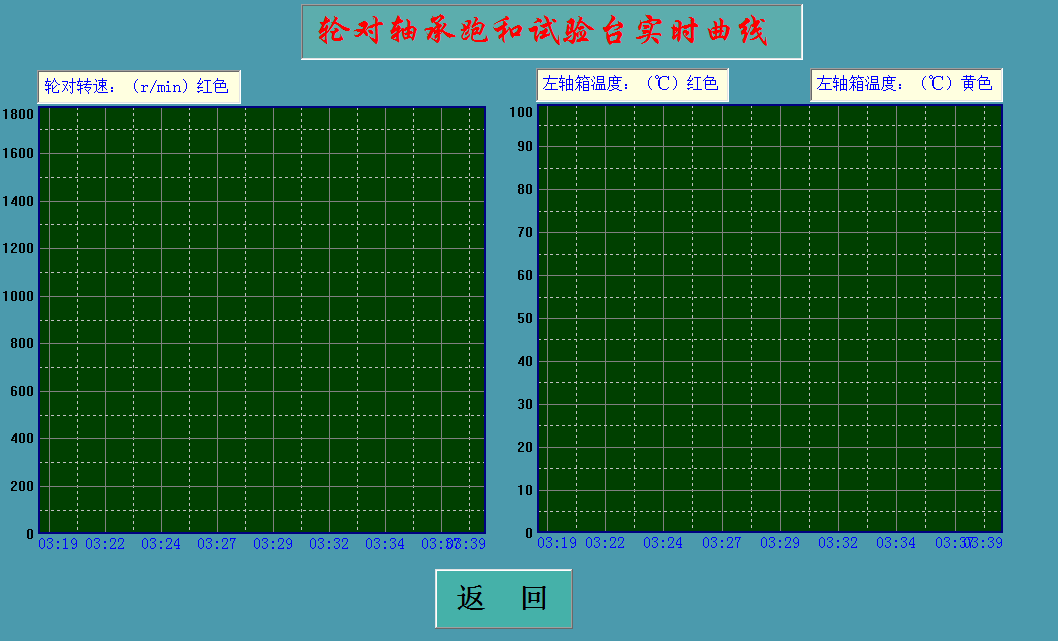

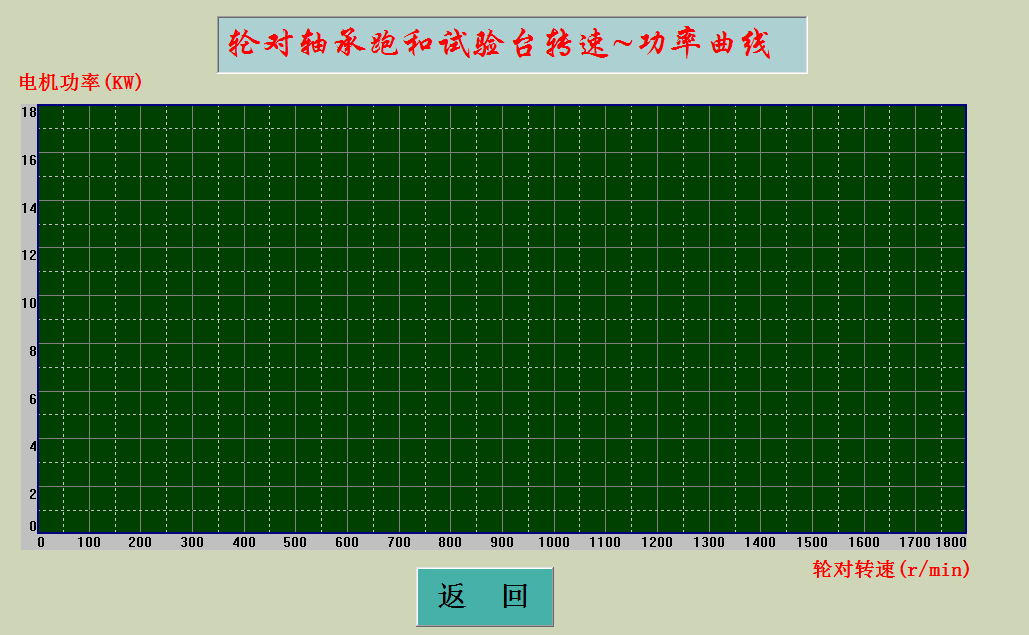

6. Device software interface